High guys quick update on my latest bodgeneering attempt with the solid mounts.

So far so good, well good ish

.slight cock up but never mind. i know about it.

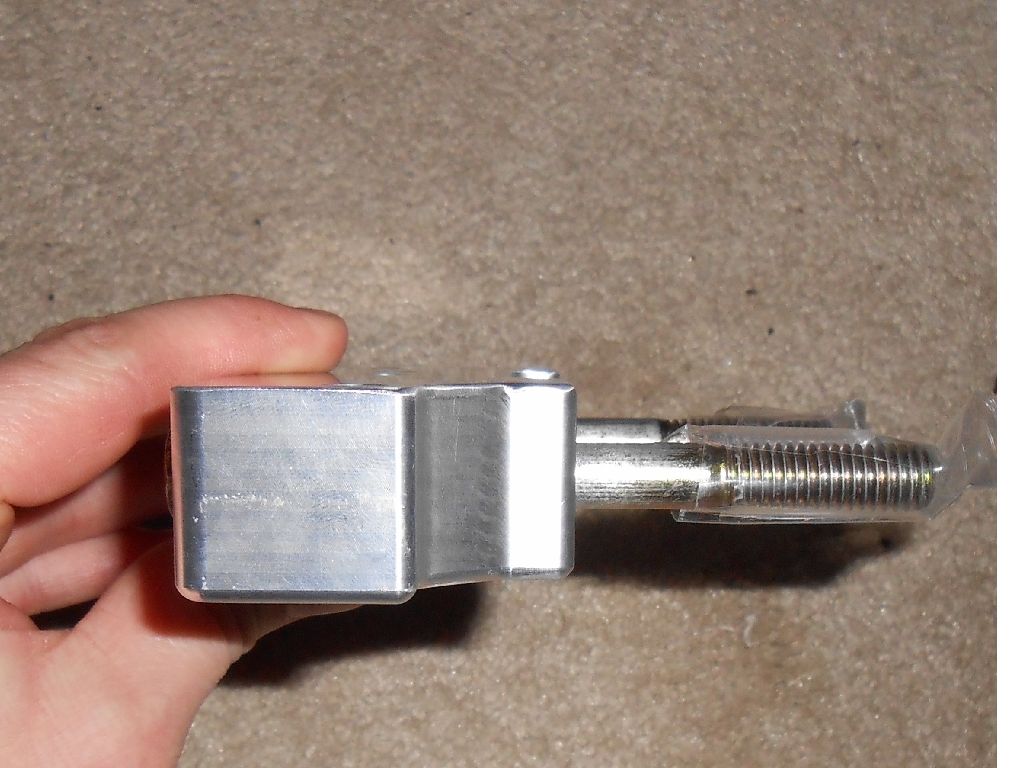

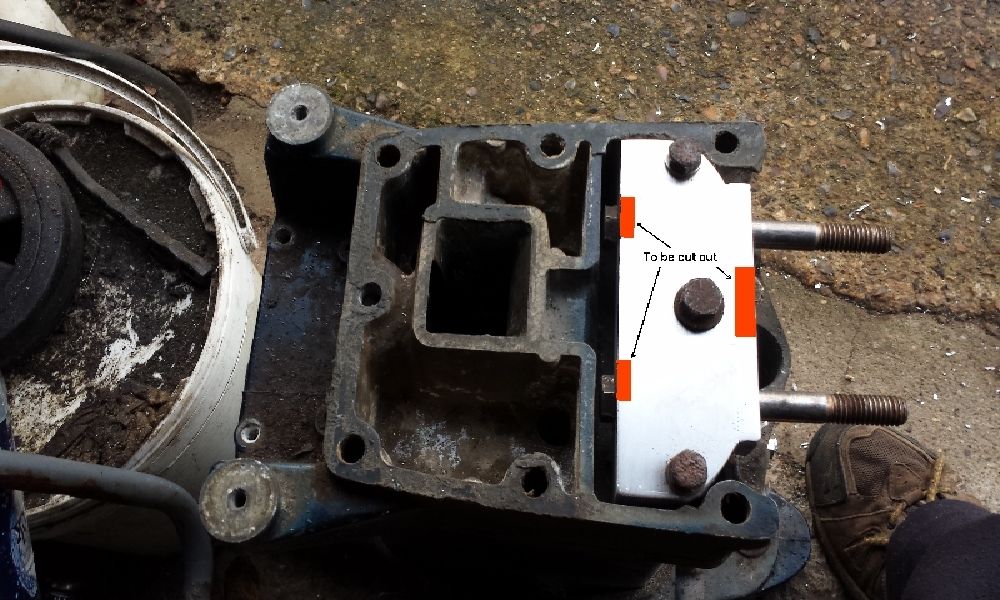

here is a couple of pics of my solid top mount so far,

remember I dont have a milling machine and I bodge stuff like this.I have made a cock up, in that the two holes for the steering bar are both off by 1 mm to the left .

when I connected up the steering bar and bottom mounts I cant see any difference with my eyes (mr magoo ).

with the original rubber mounts the top could go either way by a few mm due to engine vibration so I am hoping this

wont matter too much.

this is only the mk1, I probably wont get it right until about mk 8 ha ha ha

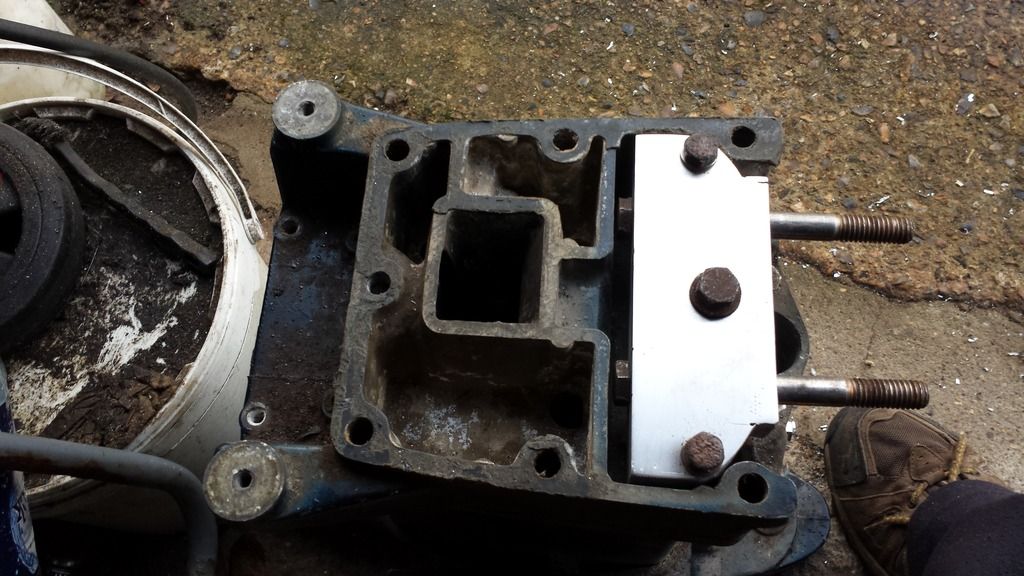

the pics are not good and it all looks way off square, but infact it fits in the top perfectly and dead square.

I still have a small section to cut away at the front of the mount where the main drive shaft comes up, this will be done

next time its dry enough for me to have electric to my garage.

( we have had so much rain in the UK , even today I had to pack away quick)

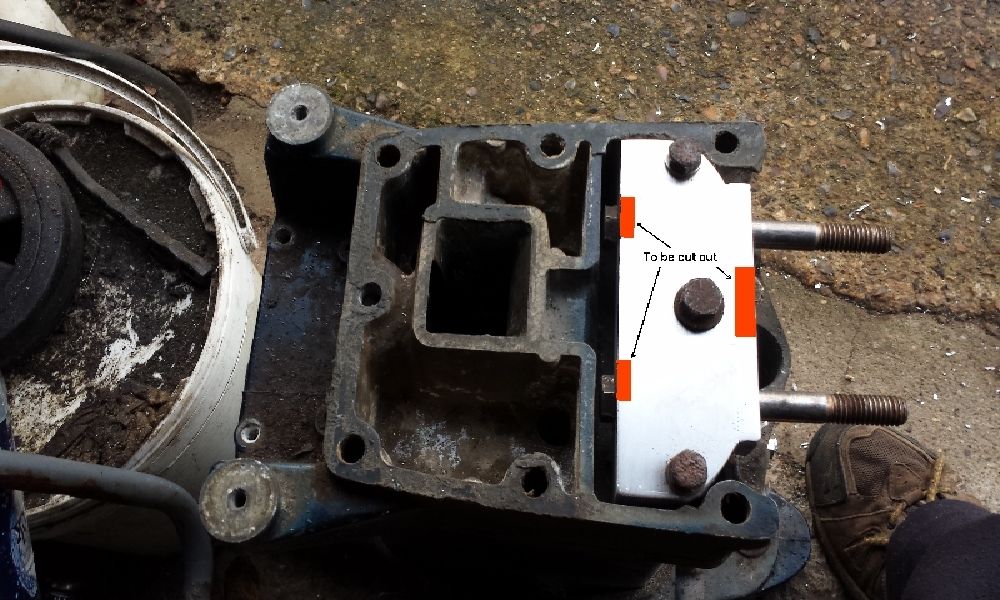

I am thinking of cutting a bit out where the bolt heads go to make them sort of captive, and just ram a piece of rubber

down the back so they cant come right out the slots if I was to loosen the nuts , why I am thinking this I have no idea,

just thought it might come in handy if I need to take engine away from bracket for any strange reason.

anyway to those who are machinists please close your eyes, coz this aint too pretty . (

Bloody brilliant for me though )

this one shows what I have yet to cut out.

.