I want make myself a set of solid engine mounts for my little 3 cylinder 70hp evinrude.

The rubbers in my top mount look as if they are about to fail, and my spares engine (same year same model)

mounts were total bad.

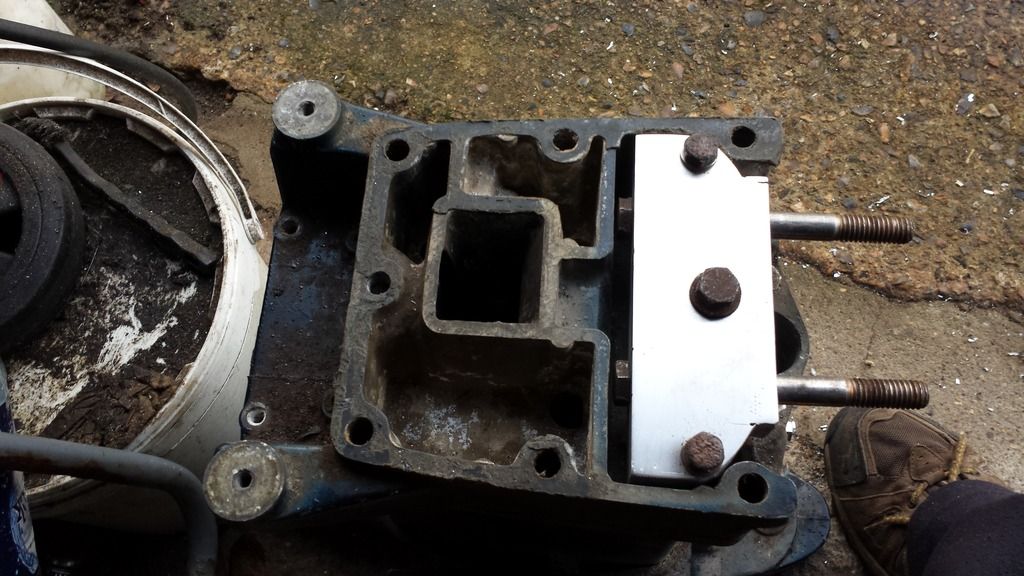

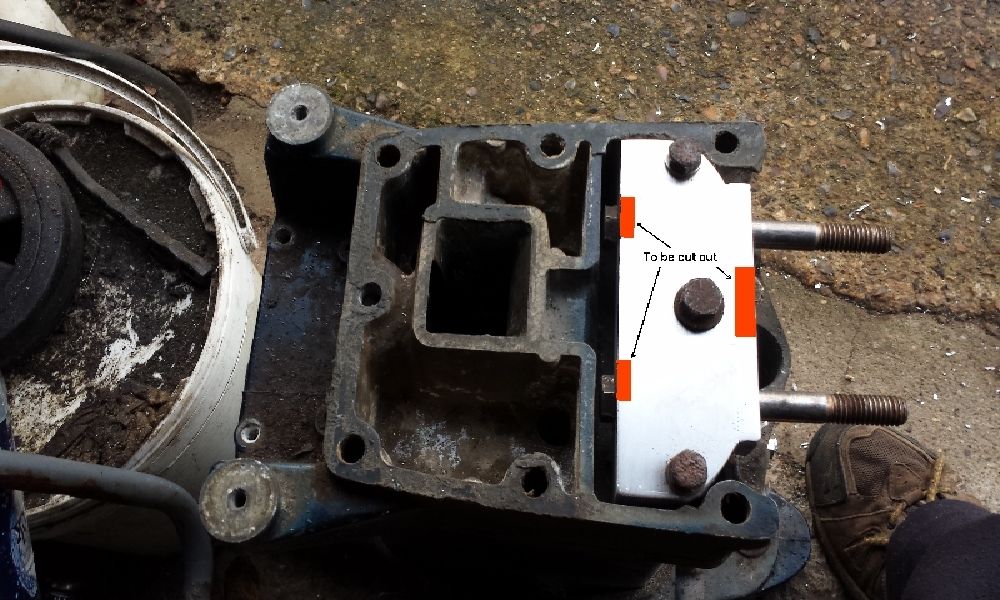

I was toying with the idea of making some solid inserts to go straight into where the rubber bushes were

but then thought maybe best to make a complete unit as it would be stronger.

what I propose to do is to use either alloy, stainless steel or solid steel bar.

Stainless would be harder for me to work with and find the side I need

ordinary steel could obviously corrode and cause a problem in the future

and with alloy it would need to be billet for cast would be total crap strength wise.

[b If using alloy billet what grade would I need, at the moment I am thinking 6082 t6 !!

does this sound right or do I need a different type ?[/b]

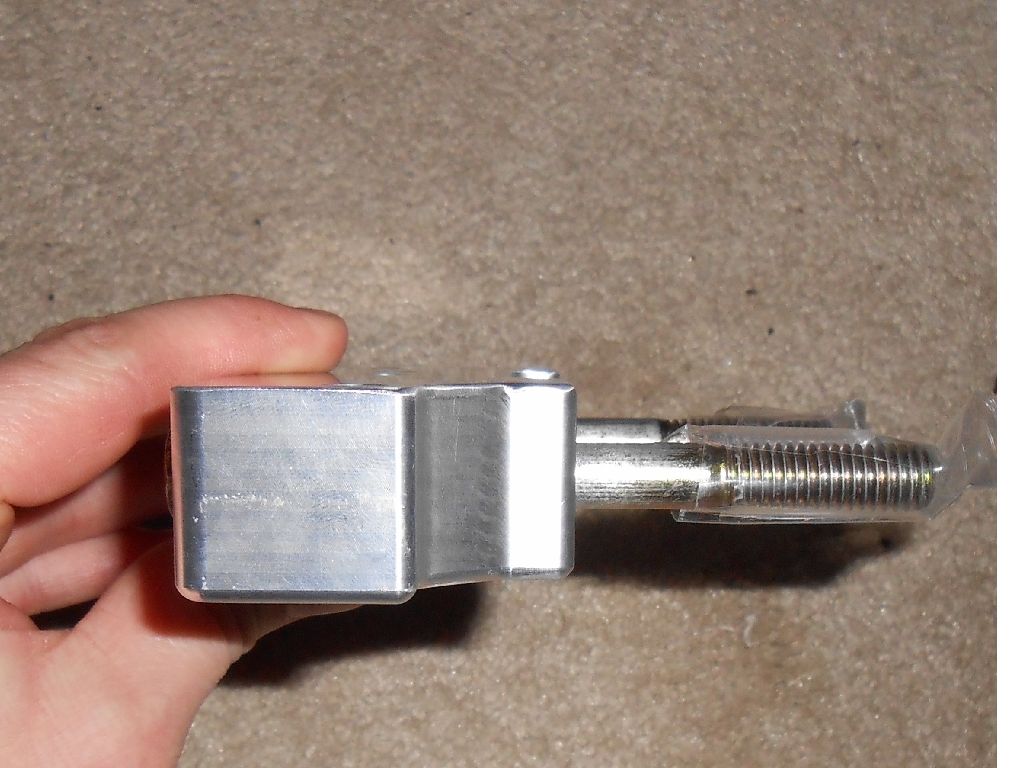

below is the type of thing I want to make, mine will be a lot uglier than that of course as

I am not an engineer and don't have a milling machine.

But I do have a good strong industrial pillar drill to get all the holes precise.

these are not mine they are taken from the net, but almost what I want.